NEWS CENTER

Gather the company's real-time dynamics, release Changbang fresh information, welcome your attention!

21

2022

-

11

The difference between particleboard and density board

The veneer MDF is processed by high temperature and high pressure after the logs are broken.

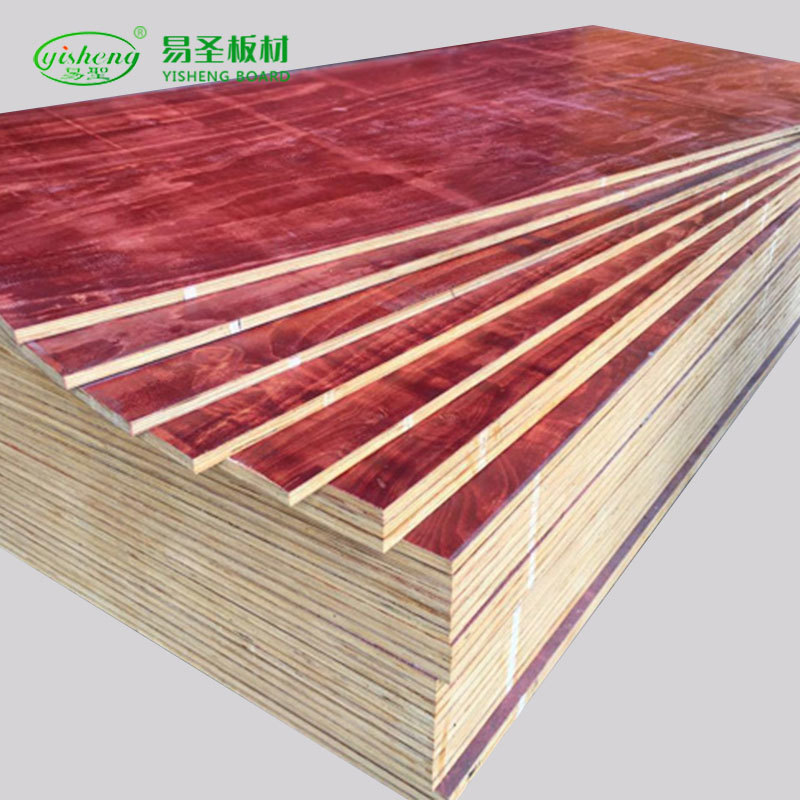

The veneer MDF is processed by high temperature and high pressure after the logs are broken. The middle layer of the board is wood blocks, and the two sides are tightly organized wood blocks, which are pressed by the boards. The surface layer is a powder layer, and the uniform particleboard is the best. The particleboard has a dense molecular structure and high bending strength. The advantage of particleboard is that it is not easy to deform and has a strong holding force. The disadvantage of particleboard is that it is not easy to bend or process the curved section, and it requires high processing machinery.

The density board is made of plant wood fiber as the main raw material, and is made by hot grinding, packaging, hot pressing and other processes. It is characterized by uniform internal structure, excellent processing performance, easy carving, and production of various shapes and shapes of parts. Density boards usually have a flat surface. Therefore, if the surface needs to be punched, milled, and molded, and the surface to be pasted is a softer material (such as a hollow plastic sheet), the density board should be used to ensure that the surface is flat after coating. Therefore, it is usually used to reinforce wooden floors and door panels.

The middle layer of the particleboard is wood long fibers, and the two sides are tightly organized wood fibers, which are pressed by wooden boards. The molecular structure is hard and the bending strength is high. The wood board has strong hardness, strong ability to not grasp, and good lateral bearing capacity, so it is suitable for connecting cabinets and wood boards.

RELATED PRODUCTS